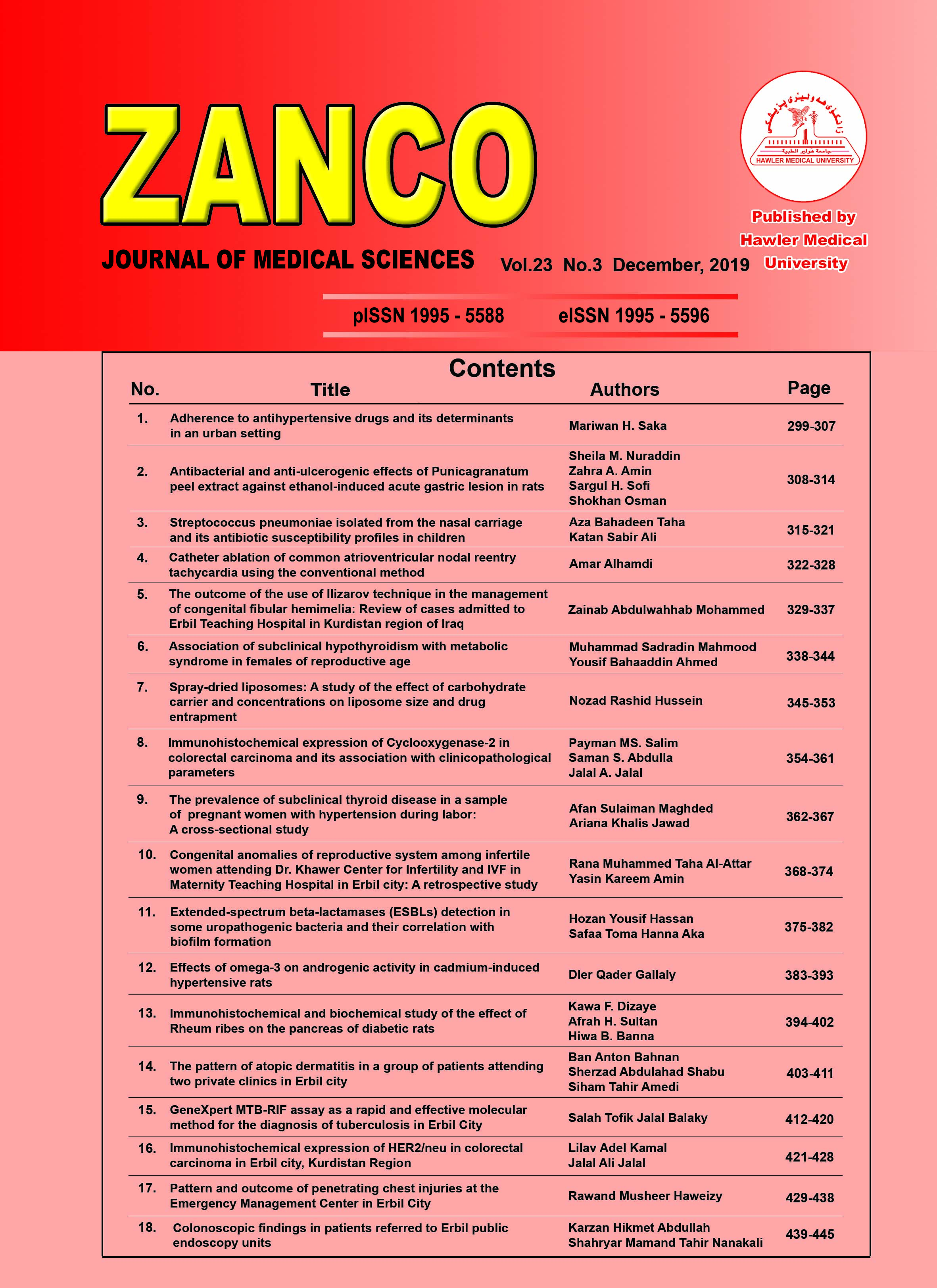

Spray-dried liposomes: A study of the effect of carbohydrate carrier and concentrations on liposome size and drug entrapment

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

- Articles

- Submited: May 12, 2020

-

Published: December 1, 2019

Abstract

Background and objective: Dry powder inhalation provide many promising features for drug delivery to the pulmonary system, such as localization of drug within the lungs, drug retention in the respiratory tract, and reduced systemic toxicities. This study aimed to prepare dry powders of liposomes containing salbutamol sulfate using spray drying and study the influence of carrier type and concentration on liposome size and drug entrapment following rehydration of liposomal powder.

Methods: Ethanol based proliposomes technique was used to generate liposomes containing salbutamol sulfate. Carbohydrate carriers: lactose, trehalose, sucrose, and mannitol in 1:6 or 1:10 (w/w) lipid to carrier ratio were separately incorporated into liposome formulations and dried by Büchi Mini-SprayDryerB-290. The protective effects of the sugars were investigated in terms of product yield (%), volume median diameter and size distribution of liposomes and entrapment efficiency of the drug.

Results: The product yield (%) of spray dried liposome formulations with carriers was in the following order; trehalose (94.02 ± 1.20%) > sucrose (69.91 ± 1.75%) > lactose (68.30 ± 1.14%) > mannitol (50.16±0.80%) for the 1:6 formulations. Depending on the carrier type and lipidto carrier ratio, the vesicle size of liposomes with lactose and mannitol increased significantly (P <0.0001 and P = 0.0027, respectively), while the vesicle size with trehalose and sucrose varied to a lesser extent (P >0.05) compared to the control formulations (3.6µm ±0.24). For 1:10formulation, the vesicle size with mannitol (P <0.001) and sucrose (P <0.001) increased significantly. The drug entrapment efficiency using the 1:6 formulations was 20.74±1.78% for sucrose, 35.59±2.42% for trehalose, 67.21±1.89 % for lactose, and 80.84±3.64% for mannitol.

Conclusion: Stable spray-dried liposomes were manufactured using sugars as carriers. The findings of this study have demonstrated the potential using of carbohydrate carriers to increase the physical stability of liposomes during the drying process, and trehalose can offer formulations with most desirable characteristics, while mannitol showed the least benefits.

Metrics

References

- Rudokas M, Najlah M, Alhnan MA, Elhissi A. Liposome delivery systems for inhalation: A critical review highlighting formulation issues and anticancer applications. Med Princ Pract 2016; 25(Suppl 2):60–72.

- Yadav AV, Murthy MS, Shete AS, Sfurti S. Stability Aspects of liposomes. Indian J Pharm Res Educ 2011; 45(4):402–13.

- Patel G, Chougule M, Singh M, Misra A. Nanoliposomal dry powder formulations. Method Enzymol 2009; 464:167–91.

- Ingvarsson PT, Yang M, Nielsen HM, Rantanen J, Foged C. Stabilization of liposomes during drying. Expert Opin Drug Deliv 2011; 8(3):375–88.

- Chennakesavulu S, Mishra A, Sudheer A, Sowmya C, Suryaprakash Reddy C, Bhargav E. Pulmonary delivery of liposomal dry powder inhaler formulation for effective treatment of idiopathic pulmonary fibrosis. Asian J Pharm Sci 2018; 13(1):91–100.

- Alexopoulou E, Georgopoulos A, Kagkadis KA, Demetzos C. Preparation and characterization of lyophilized liposomes with incorporated quercetin. J Liposome Res 2006; 16(1):17–25.

- Samborska K, Gajek P, Kamińska-Dwórznicka A. Spray Drying of Honey: The Effect of drying agents on powder properties. Pol J Food Nutr Sci 2015; 65(2):109–18.

- Chen K-H, Mueannoom W, Gaisford S, Kett VL. Investigation into the effect of varying l‐leucine concentration on the product characteristics of spray‐dried liposome powders. J Pharm Pharmacol 2012; 64(10):1412–24.

- Omer HK, Hussein NR, Ferraz A, Najlah M, Ahmed W, Taylor KMG, et al. Spray-dried proliposome microparticles for high-performance aerosol delivery using a monodose powder inhaler. AAPS Pharm Sci Tech 2018; 19(5):2434–48.

- Chougule M, Padhi B, Misra A. Development of spray dried liposomal dry powder inhaler of dapsone. AAPS Pharm Sci Tech 2008; 9(1):47–53.

- Elhissi AMA, Karnam KK, Danesh-Azari M-R, Gill HS, Taylor KMG. Formulations generated from ethanol-based proliposomes for delivery via medical nebulizers. J Pharm Pharmacol 2006; 58(7):887–94.

- Wessman P, Edwards K, Mahlin D. Structural effects caused by spray- and freeze-drying of liposomes and bilayer disks. J Pharm Sci 2010; 99(4):2032–48.

- Elhissi AMA, Islam MA, Arafat B, Taylor M, Ahmed W. Development and characterisation of freeze-dried liposomes containing two anti-asthma drugs. IET Micro Nano Lett 2010; 5(3):184–8.

- Maury M, Murphy K, Kumar S, Shi L, Lee G. Effect of process variables on the powder yield of spray dried trehalose on a laboratory spray-drier. Eur J Pharm Biopharm Off J Arbeitsgemeinschaft Für Pharm Verfahrenstechnik EV 2005; 59:565–73.

- Muzaffar K, Nayik GA, Kumar P. Stickiness problem associated with spray drying of sugar and acid rich foods: A Mini Review. J Nutr Food Sci 2015; S12:S12003.

- Omer H. Spray-dried bioadhesive formulations for pulmonary delivery [PhD Pharmaceutics]. [UK]: University of Central Lancashire; 2014.

- Hupfeld S, Holsaeter AM, Skar M, Frantzen CB, Brandl M. Liposome size analysis by dynamic/static light scattering upon size exclusion-/field flow-fractionation. J Nanosci Nanotechnol 2006; 6(9–10):3025–31.

- Larhrib H, Martin GP, Marriott C, Prime D. The influence of carrier and drug morphology on drug delivery from dry powder formulations. Int J Pharm 2003; 257(1–2):283–96.

- Alves GP, Santana MHA. Phospholipid dry powders produced by spray drying processing: structural, thermodynamic and physical properties. Powder Technol 2004; 145(2):139–48.